Mechanical Emergency Pump Starting Contactor

Mechanical Emergency Pump Start Contactor: ZSEE C1D series is specifically designed for fire water supply systems, featuring a manual mechanical emergency start function that meets the manual mechanical closing requirements of the GB/T 50974-2014 “Technical Code for Fire Water Supply and Fire Hydrant Systems.”

The product is suitable for starting and stopping control of motors with a frequency of 50Hz, a rated operating voltage of 380V, and a rated operating current of 180A or below. It can also be used in conjunction with thermal relay products to protect the motor.

The product offers two start-up modes: single direct start and star-delta direct start, catering to different power requirements for fire pump mechanical emergency start, effectively meeting the diverse needs of customers.

Compliance Standards

- GB/T 14048.1 “Low-Voltage Switchgear and Controlgear - General Rules”

- GB/T 14048.4 “Low-Voltage Switchgear and Controlgear - Low-Voltage Electromechanical Contactors and Motor Starters”

- GB/T 14048.5 “Low-Voltage Switchgear and Controlgear - Control Circuit Devices and Switching Elements - Electromechanical Control Circuit Devices”

- IEC 60947-1 “Low-Voltage Switchgear and Controlgear - General Rules”

- IEC 60947-4-1 “Low-Voltage Switchgear and Controlgear - Low-Voltage Electromechanical Contactors and Motor Starters”

- IEC 60947-5-1 “Low-Voltage Switchgear and Controlgear - Control Circuit Devices and Switching Elements - Electromechanical Control Circuit Devices”

Operating Environment

- Altitude: No more than 2000m

- Ambient Temperature: No higher than +40℃, no lower than -5℃, with an average temperature over 24 hours not exceeding +35℃

- Atmospheric Conditions: At +40℃, relative humidity should not exceed 50%; lower temperatures may allow for higher relative humidity. The average minimum temperature of the most humid month should not exceed +25℃, with the average maximum relative humidity of that month not exceeding 90%, taking into account condensation on the product due to temperature changes.

- Pollution Degree: Grade 3

- Installation Category: Category III

- Installation Conditions: The installation surface should not tilt more than +5° from the vertical plane.

- Impact and Vibration: The product should be installed and used in places without significant shaking, impact, or vibration.

Model Description

Note ①: Depending on the current and starting mode, the ZSEEC1D series can be equipped with various specifications of external operating handles. Refer to the table of handle models and appearances at the end of the sample. Please confirm the specific handle specifications and model with the commercial department before ordering.

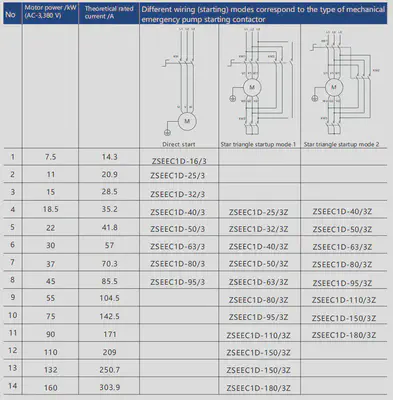

- Rated Current Values: 16, 25, 32, 40, 50, 63, 80, 95, 110, 150, 180

- Starting Mode: Star-delta start marked as Z, single direct start not marked

- Control Power Voltage:

- 16~95: 127, 220 (not marked), 380

- 110~180: 110, 220 (not marked), 380

- Manual Mechanism Auxiliary Contact Description: 16~180 default configuration is 2 normally open, 2 normally closed

- Contactor Auxiliary Contact Description: 16-95 products have one normally open and one normally closed switch; other currents do not include auxiliary contacts. For configuration with side-mounted auxiliary contacts, refer to the table below.

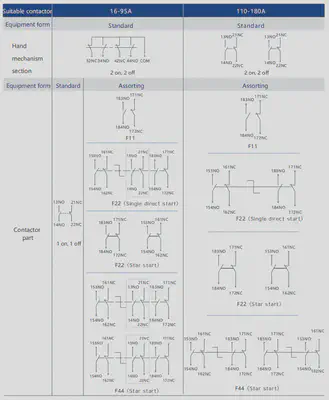

| Start Mode | Current Range | Auxiliary Contact Model | Contact Type | Description |

|---|---|---|---|---|

| Single Direct Start | 16-180 | F11 | 1NO 1NC | Optional F8-11 auxiliary module, can be factory pre-installed or self-assembled |

| Single Direct Start | 16-180 | F22 | 2NO 2NC | Optional F8-11 auxiliary module, can be factory pre-installed or self-assembled |

| Star-delta Start | 16-180 | F22 | 2NO 2NC | Optional F8-11 auxiliary module, can be factory pre-installed or self-assembled |

| Star-delta Start | 16-180 | F44 | 4NO 4NC | Cannot be self-assembled, must be factory pre-installed |

Note: If a single direct start contactor is selected, F11 is pre-installed by default on the right side; if a star-delta start contactor is selected, the auxiliary contacts should be equipped with one set for each of the two switches, with F22 pre-installed by default in the middle of the mechanism.

Example of Selection:

-

32A single direct start external operation, 220V control voltage, selected with one normally open and one normally closed side-mounted auxiliary contact model: ZSEEC1D-32/3JF11

-

180A star-delta start external operation, 380V control voltage, selected with four normally open and four normally closed side-mounted auxiliary contact model: ZSEEC1D-180/3ZJ380F44

Accessory Models (Separate Selection)

| le | Switch Auxiliary | Remarks |

|---|---|---|

| 16-95 | F8-11 | Side-mounted |

| 110-180 | F8-11 | Side-mounted |

Product Features

- Equipped with a manual operation forced closing function, meeting the manual closing requirements of fire pumps.

- Mature mechanical structure ensures stable and reliable manual start.

- The product contact system uses silver-based contacts, ensuring connection and disconnection capabilities.

- Additional accessories are flexible and convenient.

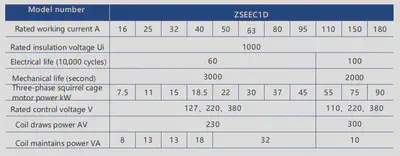

Technical Parameters

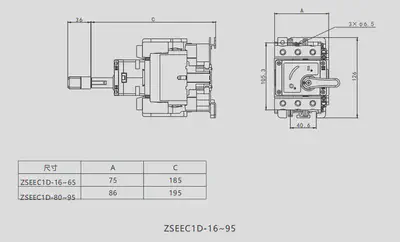

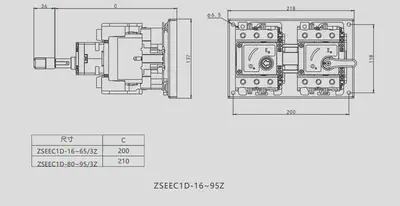

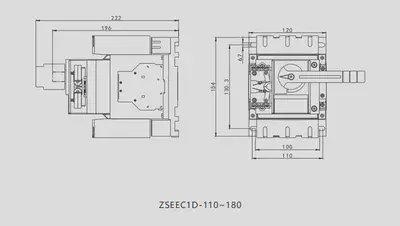

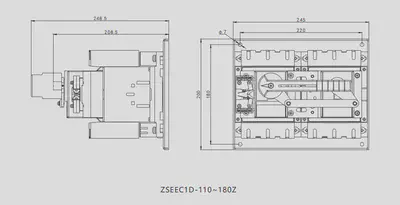

Dimensions and Installation (Unit: mm)

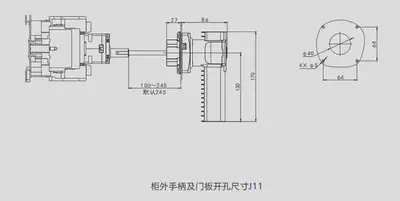

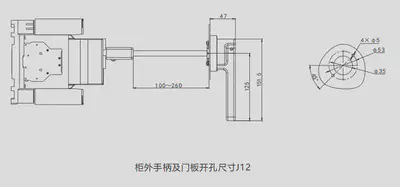

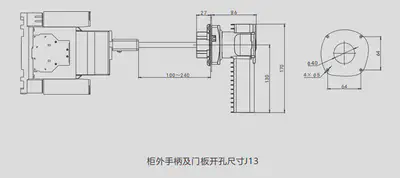

Handle Models and Appearance Table

Auxiliary Contact Terminal Diagram

Model Comparison Table

Note:

- All motors and accessories mentioned in this scheme are produced by regular manufacturers and strictly comply with national standards.

- The model comparison table is for typical design applications only. Actual selection can be made based on on-site design and usage conditions.

- The star-delta start model in the figure refers to the main contactor and angle contactor models, and the star contactor needs to be selected separately.

Due to continuous technological upgrades and optimizations of our company’s products, all information contained in this document is subject to the actual product. Changes may occur without prior notice. Our company and its employees do not assume any joint liability for disputes arising from information in this document not confirmed by our business department.