Transformer Fault Diagnosis and Energy Consumption Monitoring Device

Transformer Fault Diagnosis and Energy Consumption Monitoring Device: ZSEE Powersafe series requires only the collection of CT and PT signals from both the high and low voltage sides of the transformer to diagnose its safety status. In the event of a fault, it can perform online analysis and diagnosis of the fault type and severity. It also monitors parameters such as no-load and load losses, three-phase imbalance, and harmonics of the transformer.

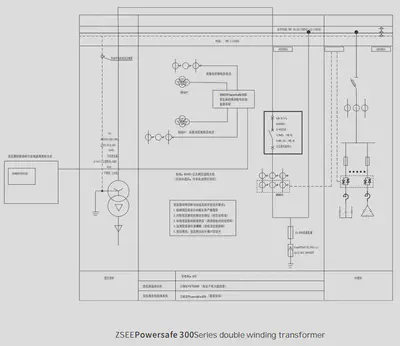

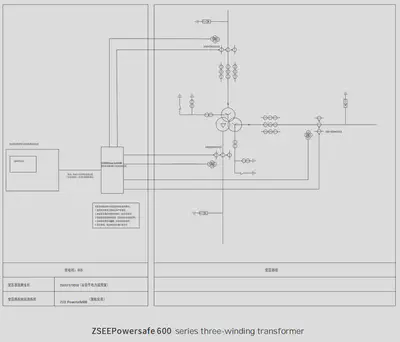

Transformer Voltage Levels:

- 300: Distribution transformer voltage levels 10kV-35kV

- 600: Power transformer voltage levels 110kV-500kV

- 900: Power transformer voltage levels 750kV and above

Main Functions

The main functions of the ZSEE Powersafe fault diagnosis and monitoring system:

- Diagnose whether the transformer has faults and their severity;

- Diagnose the types of transformer faults, such as partial discharge, winding deformation, and excitation system faults;

- Diagnose the location of the transformer fault, such as the high-voltage winding of the A-phase column.

Product Features

Product Advantages

The world’s first power monitoring device using the holistic electrical quantities (voltage and current) of power transformers as signal sources.

Product Advantages

- Does not involve primary equipment of the system and does not require special devices and sensors. It can perform diagnosis and monitoring using shared data from any set of voltage and current protection, metering, monitoring, or recording.

- Highly versatile, with diagnostic and monitoring methods applicable to a wide range of scenarios. Suitable for power transformers in operation, distribution transformers (oil-immersed, dry-type, box-type), and for intermediate, transfer, acceptance, and withstand voltage tests during maintenance. Also applicable for quality supervision and inspection during the production of large electrical equipment like transformers.

Innovations

A new method is proposed using the holistic electrical quantities (voltage and current) of power transformers as signal sources to perform multi-scale diagnosis of transformer faults and defects. This method enables multi-scale sectional diagnosis for bushings, cores, and windings.

ZSEE Powersafe Series Transformer Fault Monitoring Device Principles

Proposed a criterion for fault diagnosis based on nonlinear mapping of system total energy variation and rate of change.

Any actual engineering system’s state changes comply with the conservation of matter and energy systems. The energy from local high-temperature arcs or overheating faults must ultimately be borne by the energy supply system. Both normal and fault states correspond to a determined energy state of the energy supply system. The change in energy and its rate are key indicators for identifying faults in electrical equipment.

Therefore, the project development team proposed constructing a nonlinear mapping (Nonlinear Mapping) NMP1 (dw, dw/dt) using system total energy variation and rate of change as variables as a criterion for identifying electrical equipment faults.

Proposed a criterion for fault diagnosis based on the probability of abnormal energy changes over a certain period.

All actual engineering systems inherently have nonlinear and uncertain characteristics, and the faults of electrical equipment have a certain randomness. Therefore, the project development team proposed using the probability (Probability) NMP2 (P(dw, dw/dt)) of abnormal energy changes over a certain period as the second criterion for identifying electrical equipment faults.

Proposed a criterion for fault diagnosis based on the polarity effect corresponding to system energy variation and rate of change.

The insulation defects of high-voltage electrical equipment are not man-made. The equivalent electrode system that generates local arcs or high-temperature overheating faults mostly has a rod-plate structure, generally exhibiting a polarity effect (Polarity Effect). Therefore, the project development team proposed using the polarity effect NMP3 (PE(dw, dw/dt)) of system energy variation and rate of change as the third criterion for electrical equipment fault diagnosis.

The Necessity of Installing Transformer Fault Diagnosis Systems

Transformer Safety Operation Requirements

Currently, most distribution transformers in China are dry-type and primarily use temperature protection. As is well known, using a fan to dissipate heat cannot solve the internal fault of the transformer when overheating occurs, and insulation faults account for 85% of transformer faults. The installation of the ZSEE PowerSafe product enables timely diagnosis and analysis of transformer insulation faults, providing early warnings of major accidents to ensure safe production. Additionally, offline maintenance of transformers does not fully reflect their operating state online, making ZSEE Powersafe’s online fault diagnosis a more accurate representation of transformer operation.

Energy Conservation and Emission Reduction Requirements

To thoroughly implement the “Energy Conservation Law of the People’s Republic of China” and the Ministry of Industry and Information Technology’s Order No. 33, “Transformer Energy Efficiency Improvement Plan (2021-2023)”, transformer losses account for over 40% of total transmission and distribution losses. The regulation clearly stipulates eliminating high-energy-consuming transformers, promoting material innovation and technology upgrades for high-efficiency energy-saving transformers, and developing intelligent operation and full lifecycle management technology to improve the digital, intelligent, and green levels of transformers.

The ZSEE PowerSafe series can monitor the no-load and load losses of transformers, timely identifying unqualified transformers. When a transformer has faults or defects, significant energy losses occur. The ZSEE Powersafe transformer fault diagnosis device can promptly alert users to take appropriate measures to achieve energy-saving effects.

Product Design Illustrations

System Overview

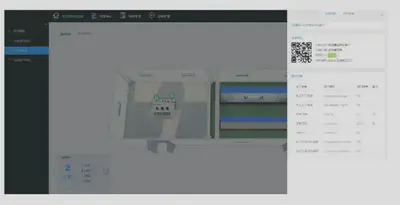

The ZSEE Transformer Monitoring Cloud Platform is a new-generation intelligent transformer monitoring system platform based on Internet technology and wireless communication technology. It can quickly and accurately store the transformer’s real-time status information and operating data in an encrypted format in a cloud data warehouse, perform real-time comprehensive sorting and analysis, and issue early warning prompts through the cloud platform or local system host in case of transformer abnormalities.

The ZSEE Transformer Monitoring Platform makes full use of various transformer parameters, highly integrating cloud data and Internet applications to perform comprehensive analysis, judgment, and decision-making on various related data of transformers in operation, forming a comprehensive safety view of the transformer. It assists relevant management personnel in implementing transformer safety handling plans. The ZSEE Transformer Monitoring Cloud Platform can also send real-time updates on transformer operating conditions via SMS, mobile apps, WeChat, and other channels, providing users with higher-quality and more convenient safety services to ensure the safe operation of transformers.

System Composition

The ZSEE Transformer Monitoring Platform consists of terminal devices located at the data collection layer and a cloud data warehouse. As a new technology for transformer monitoring, it uses big data to collect and track various data on the transformer’s working status in real-time. The ZSEE Transformer Monitoring Platform’s data processing system automatically analyzes suspicious data and pushes abnormal early warning information to users.

Users can access the ZSEE Transformer Monitoring Cloud Platform at any time through fixed or mobile network communication devices to remotely monitor the operating status information of the monitored transformers in real-time, achieving true mobile remote operation and maintenance. For non-professional users, daily transformer operation and maintenance work can be entrusted to professional maintenance and testing companies, which can monitor transformer operating parameters in real-time through the ZSEE Transformer Monitoring Cloud Platform. This improves professional and efficient operation and maintenance plans, helping users grasp transformer operating conditions in a timely manner and reducing the risk of sudden transformer accidents.

Transformer Operating Status and Energy Consumption Monitoring Platform

System Interface

Cloud Platform Features

Unified Management, Centralized Monitoring

The system can manage and monitor the operation safety and energy consumption of all transformers in the entire area through the platform.

Cloud Storage, Big Data Analysis

All core data of the ZSEE transformer operating status and energy consumption monitoring platform is stored in real-time through the cloud data warehouse. Comprehensive analysis is conducted using big data to identify suspicious data points for early warning processing.

24-Hour Online Service

The ZSEE transformer operating status and energy consumption monitoring platform’s 24-hour online service function provides early warnings in case of faults, reducing the workload of monitoring personnel. The fully automated information push mode also lowers the requirement for the professional skills of monitoring personnel.

Process Monitoring and Active Management

The ZSEE Transformer Monitoring Cloud Platform can identify transformer fault types and severity based on collected operational parameters, providing convenience and technical support for maintenance personnel.

Objective and Effective Accident Traceability

The ZSEE Transformer Monitoring Cloud Platform stores all safety data of transformers under its jurisdiction in a cloud repository, and performs special storage of relevant data before and after accidents to prevent data tampering, ensuring the effectiveness of data traceability.

- Due to the continuous upgrade and optimization of the company’s product technology, all information contained in this document is subject to the actual product. Any changes are subject to change without notice. The company and its employees do not bear any joint liability for disputes arising from information in this document not confirmed by our business department.