Meeting Customer Customization Needs and Services

Meeting Customized Client Needs and Services

From product planning, design and development, production, and delivery to after-sales, we possess a mature complete-machine delivery capability to help clients bring advanced products to market.

R&D and Design Capabilities

- Advanced structural and system design capabilities, as well as professional performance testing software development.

- Continuous annual increase in R&D investment, attracting top talents, cutting-edge technologies, and advanced R&D equipment.

- Strong technical strength, with technical talent accounting for 60% of the team.

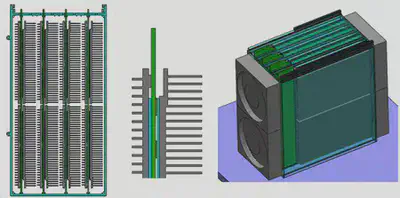

Structural Design

Whole-machine structural design for mining machines: This includes casing design, structural design, packaging design, and mold manufacturing, with process analysis and product design conducted based on clients' technical parameters, and scientific material selection. This applies to components such as mining machine cases, top covers, baffles, etc.

System Design

Mining machine system operating software design: This includes the design and development of control board systems, mining systems, and management systems, along with distributed storage mining machine system development; layout of thermal simulation design; group control software and after-sales maintenance software design and development; and development of other production testing software for individual machines.

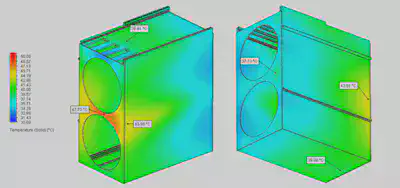

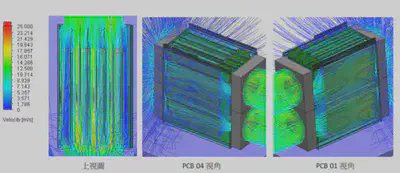

Thermal Simulation Design

Thermal simulation design: Using numerical software to build numerical models of mining machines, virtual experiments are conducted for thermal simulation at the ASIC chip level, PCB level, and system level, to effectively assess the heat dissipation performance and feasibility of the mining machine.

Group Control Software

Group control software: Mining farm intelligent monitoring desktop management software that enables remote control of mining machines, real-time management, and the simultaneous management of multiple mining machines. It supports bulk monitoring of machine statuses, bulk configuration, firmware upgrades, restarts, etc.

Individual Machine Software

Production testing software: This includes full-machine testing software for mining machines, control board production testing software, chip testing software, control board OTA upgrade system, control board mass production MAC detection software and MAC address programming software, production data query system, network testing tools, burn-in software, and communication interface testing software to ensure product quality.

Maintenance Software

After-sales maintenance management software: This software manages the entire after-sales maintenance process, quickly locating fault causes and resolving issues promptly. It is used during the after-sales phase to enhance product management and tracking, providing real-time data analysis.

Manufacturing Capabilities

- Domestic and overseas manufacturing bases, coordinated production, ensuring global delivery.

- Equipped with advanced production equipment, with modern workshops integrating production, assembly, and warehousing.

- A professional team for model selection and procurement management ensures the stability of the production supply chain.

- Strict quality standards and inspection protocols are implemented to guarantee product quality.

After-Sales Service Capabilities

- A comprehensive after-sales service system supports systematic analysis of after-sales data, identifying faulty data, trends, and providing warnings.

- Rapid response to customer needs, promptly addressing and resolving complaints.

- Comprehensive analysis of after-sales maintenance data, risk warnings, and quality improvements.